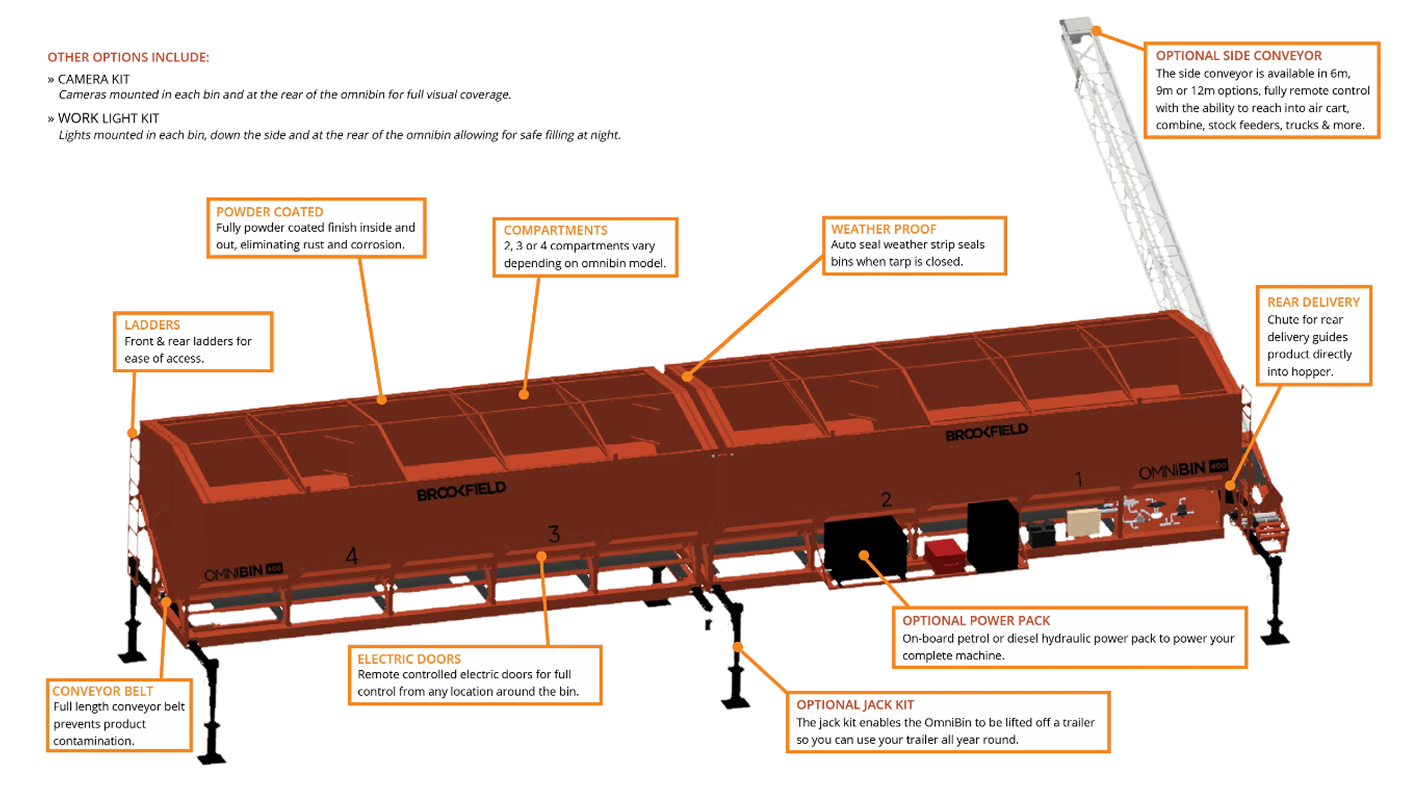

The Most Versatile Commodity Bin for Australian Farmers

What is the BROOKFIELD™ OMNIBIN?

Capacity | OB60 | OB90 | OB120 | OB150 | |

|---|---|---|---|---|---|

Tonnes | (av. wheat/urea) | 4.5 | 7 | 9 | 11.5 |

Tonnes | (Av. fertiliser) | 6 | 9 | 12 | 15

|

Mounted on Chassis | OB60 | OB90 | OB120 | OB150 | |

|---|---|---|---|---|---|

Dimensions | Length | 5.7m | 6.9m | 8.2m | 9.5m

|

Width | 2.5m | 2.5m | 2.5m | 2.5m | |

Height | 3.1m | 3.1m | 3.1m | 3.1m |

Bin Only | OB60 | OB90 | OB120 | OB150 | |

|---|---|---|---|---|---|

Dimensions | Length | 3.2m | 4.4m | 5.7m | 6.9m |

Width | 2.3m | 2.3m | 2.3m | 2.3m | |

Height | 2.0m | 2.0m | 2.0m | 2.0m | |

Tray Length Required | 2.6m/8.5ft^ | 3.8m/12.5ft^ | 5.1m/16.7ft^ | 6.3m/20.7ft^ | |

Conveyor Overhang | 1.4m | 1.4m | 1.4m | 1.4m | |

Tare Weight (kg) | 950 | 1,400 | 1,850 | 300 |

…It just keeps getting better!!

Side Conveyor Model | OBSC60-MR |

|---|---|

Height *Based on a chassis height of 1.1m | 2.5m |

Reach | 3.5m |

Sowing season on Mal’s Harden property used to be a high-pressure juggling act. Refilling the seeder with grain and fertiliser was a time-consuming, two-person job, requiring a split-bin tipper and auger. As the bins emptied, the team had to manually shovel fertiliser, creating safety risks and slowing operations.

To complicate matters further, with three bins on the seeder, they also needed a separate bin for urea, which tied up extra machinery and people during a time-critical window.

Time & Labour Efficiency:

Harvest Operations:

With the Brookfield OmniBin OB200 now a key part of the farm’s operation, Mal’s team is enjoying a safer workplace, greater flexibility, and the confidence to potentially expand crop area without needing more capital or equipment.

“It’s a smart, long-term investment that’s already proving its worth across seasons.”

– Mal, Harden NSW

BROOKFIELD impressed us from the first meeting when a representative came out to see our soils, needs and challenges and set up the ChainBar for optimum performance. At some point when we found wear and tear on the chains, BROOKFIELD sent a delegation down to troubleshoot and amend our challenges. Thanks for the great support.

“We recently purchased an OB320 OmniBin with a 12m Conveyor as we were experiencing contamination issues with our previous grouper. The OmniBin is wonderful to use, it has got the remote-control system, and everything works so smooth with the conveyors.”

“Magnificent machine – the best $XXX I’ve ever spent – awesome machine. It turned up, it was set up well and it worked – marvellous – I love it – thank you.”

“I’ve been able to significantly improve my operation since 2006 when I invested in my first BROOKFIELD machine – I now run three. They have proven their performance by vastly reducing our spraying costs, improved soil composition through stubble mulching and rid us of wheel track problems.”

“The CrossBar has reduced our mowing by 80% and we use it to level our mid-rows which has reduced the wear and tear on our other machinery. It’s been beneficial in seedbed preparation before planting and we have used it for bearing the earth to help with the impact of frosts.”

“This was a luxury we didn’t think we needed but now couldn’t live without. It’s a necessity for a modern operation of our size.”

Part of a family of brands driving innovation across Australian agriculture